-

JUL26

5 Comments by AdminRecycling and its challenges with Expanded Polystyrene!

Recycle! This word has been resonating around us since centuries it seems. Recycling as we all know is a process of converting waste material into new materials and objects for reusing. Although it sounds simple, the word recycle always pops questions like why, how, what, when and many more for a consumer.

Recycle! This word has been resonating around us since centuries it seems. Recycling as we all know is a process of converting waste material into new materials and objects for reusing. Although it sounds simple, the word recycle always pops questions like why, how, what, when and many more for a consumer.

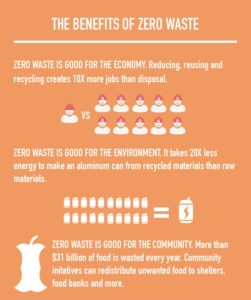

Apart from the environmental benefits which are usually discussed, recycling has various socio economic benefits. Recycling provides a boost in the economy by providing a number of jobs and saving costs on manufacturing new products. The question that needs to be asked here is ‘Where does all the waste from the garbage bin, we usually throw our waste in, goes?’

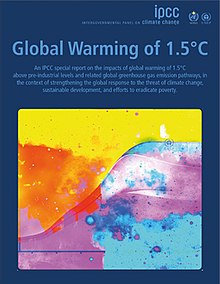

Things we do not recycle usually ends up in a landfill. Landfills which are a hazard in itself, release methane and carbon dioxide (the two major greenhouse gases) into the atmosphere. Landfills are the third largest producer of methane emissions in the United States of which 95% is from solid waste landfills. The CPCB (Central Pollution Control Board, India) has claimed that almost 77% of the collected waste in India remains untreated and is a major contributor to the Green House Gas emissions.

The IPCC (Intergovernmental Panel on Climate Change) has recently released a new report claiming that the global warming is likely to reach 1.5 degree Celsius between 2030 and 2050 if it continues to increase at the current rate. As alarming as this sounds (if you are not alarmed, go to their website to read the report) one of the only ways to stop this is by reducing the greenhouse gas emissions.

Hence, recycling plays a key role to avoid the environmental challenges that are to come. The process of recycling is perceived as strenuous by most. This is because of its different shortcomings. Each material has a different recycling process, which poses the other issue of segregation and each process requires a different set of equipment and process. Each of these also have their own long list of criteria associated.

Hence, recycling plays a key role to avoid the environmental challenges that are to come. The process of recycling is perceived as strenuous by most. This is because of its different shortcomings. Each material has a different recycling process, which poses the other issue of segregation and each process requires a different set of equipment and process. Each of these also have their own long list of criteria associated.

A lot of steps are being taken by the government across different countries to make the process of segregation and waste management as easy and efficient as possible. A study shows that the current, rather isolated efforts, in different systems for waste management, waste reduction and resource management are not sufficient in a long term sustainability perspective. This again brings us to a solution where maximum work needs to be done at the consumer end and better collection and segregation systems need to be established.

One such material always associated with recycling issues is Expanded Polystyrene. More often than not EPS Scrap ends up in the landfill and is untreated. Expanded Polystyrene or thermocol (as it is commonly known in India) was founded by german researchers in 1839 and was an immediate success due to its flexible and moldable nature once it was introduced to the market in 1937. Expanded Polystyrene products have had a good run for over a 100 years. Unfortunately, due to less awareness of its recycling properties and a few restrictions a lot of countries have started banning certain products made from EPS. Now the question is the sustainability impact of potentially more product damage and its related carbon footprint and economic cost on one side of the debate if EPS packaging is not used, to the sustainability dilemma of ocean plastic and solid waste generation resulting from using EPS, on the other.

We are actively working towards the second part by using the magic of recycling. It needs to be un

derstood that Expanded Polystyrene is a 100% recyclable product. Limitations arise due to its volume which makes the transport of the waste product extremely difficult. The same features that make EPS popular also make it a challenge to recycle: namely, its low density, which can make closing the loop very costly. EPS is 98 percent air, which, when contained in bulky, hard plastic shapes, can become remarkably expensive to transport. The fact is that it’s often easier and cheaper to produce new polystyrene than it is to collect, transport and process material for recycling and we are actively trying to change this at our company.

We, at Penguin Polyfoam Pvt. Ltd. provide recycling services for EPS. As manufacturers, we recycle all of our EPS waste into pellets. The recycled EPS pellet can be then used for making various products such as photoframes, seedling trays, coat hangers, cornices and skirting, safety helmets etc. Simultaneously we have also developed a recycling program under which we carry out awareness drives to collect EPS Scrap and educate the end users about the recycling capabilities of EPS. Under this program we are trying to develop a channel system to collect EPS scrap from consumers/producers such as electronic retail stores, residential colonies, educational institutes, food waste collectors. This way collection can be made easier with collaborations. With this initiative we are looking to gradually eradicate the EPS recycling issue in our city and make EPS collection, segregation and recycling an organised process.

Here’s to a zero waste lifestyle! We urge everyone to do as much as possible to reuse, reduce and recycle in their day to day life and be conscious of the waste you produce.

Read More